Classification of air conditioning systems

There are several different ways of classifying air conditioning systems

Classification as to major function. Air conditioning systems are of two basic types as far as their functions are concerned.

Comfort air conditioning systems

The purpose of these systems is to create atmospheric conditions conducive to human health, comfort, and efficiency. Air conditioning systems in homes, offices, stores, restaurants, theaters, hospitals, schools, and churches are of this type.

Industrial air conditioning systems

The purpose of these systems is to control atmospheric conditions primarily for the proper conduct of research and manufacturing operations. Manufacturing tolerances in the electronics, space, and computer industries and in all high-speed automated manufacturing are such as to require absolute control of temperature, moisture, and air purity. Air conditioning systems in paper mills, textile mills, candy factories, and printing or photo processing plants are also essential for these industries. Some of these industrial systems incidentally serve human comfort, but some do

not.

Classification as to season of the year

Winter air conditioning systems

These systems, when properly designed and installed, maintain indoor atmospheric conditions for winter comfort, namely, temperature, humidity, air purity, and air movement. The major problems of winter air conditioning are to heat the air and bring the moisture content (humidity) up to an acceptable level.

Winter heating is accomplished by distributing heated air to spaces by ductwork or by circulating hot water, steam to fin-tube radiation or to convectors or fan-coils. Heat is supplied by furnaces, by hot water steam boilers fired with gas, oil, or coal, by electrical resistance heaters, by electrically driven heat pumps; or by solar energy collectors. Humidification of the air in the heated space is often necessary to attain a comfortable condition.

Humidifiers may be of the simple pan type or spray type or the more complex rotary type. Electric heating by resistance elements has many applications in residential, commercial, and industrial fields.

Summer air conditioning systems

These systems control all four atmospheric conditions for summer comfort. The major problems are to cool the air and to remove excess moisture from it. Cooling is ordinarily accomplished by mechanical refrigeration. Removal of the moisture (dehumidification) is accomplished as condensation of water vapor in the air occurs on cold coil surfaces.

Year-round air conditioning systems

These systems are composed of heating and cooling equipment with automatic controls and associated components to produce the four atmospheric conditions for human comfort at all times of the year.

Classification as to equipment arrangement

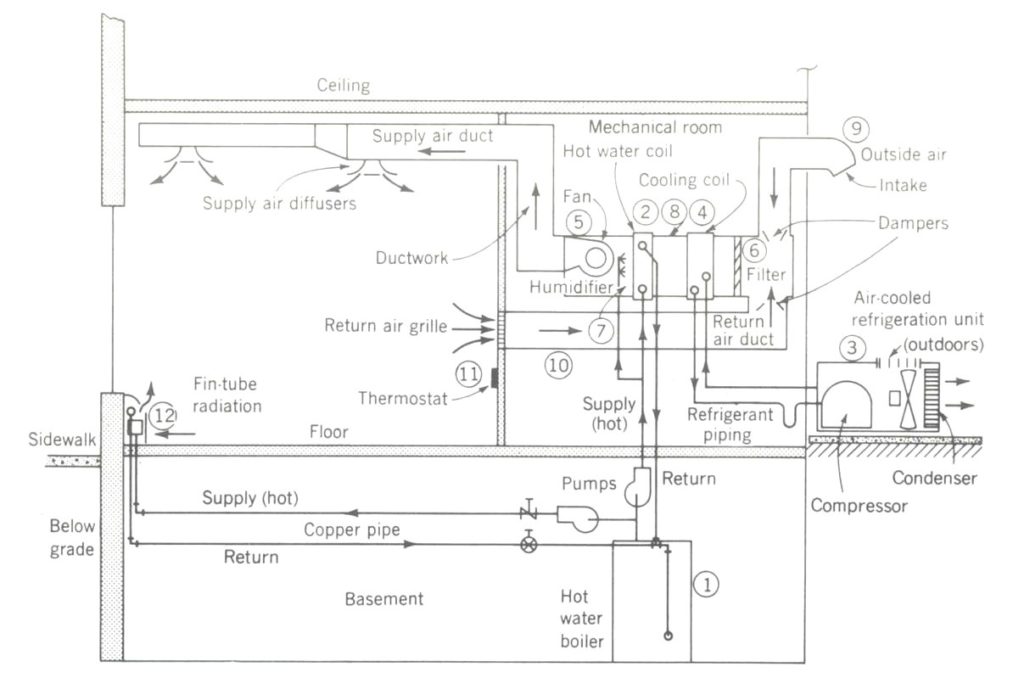

Combination systems

This type of system combines the features of central-station and unitary systems. The heating and refrigeration equipment is in a central mechanical room. Heat energy is supplied in pipes to the several unit air conditioners in the form of steam or hot water. Chilled water from the central refrigerating equipment is also piped to the air conditioners. Air conditioning units may be installed in and serve a single room, or they may serve several rooms from a location above a suspended ceiling by short runs of duct work. The performance of the air conditioning unit is controlled by thermostats in the rooms or spaces they serve.

Air Conditioning System Components

- A condensing hot-water boiler supply hot water under pressure and at a temperature of about 65°C.

- How-water coil in the air conditioning unit. This coil is made up of many turns of copper tubing, with multiple copper or aluminum fins, to transfer the heat to the air as it is blown over the coil. Hot water may also be pumped to fin-tube radiation for extra heat near an outside wall or display window.

- The refrigerating machinery is compressor, driven by an electric motor, with an air-cooled condenser. The compressor uses a refrigerant and the condenser supplies this refrigerant as a liquid to the cooling coil.

- In the cooling coil the liquid boils off, or evaporates, at a temperature of about 4.5°C. When the system is on the cooling cycle with the proper amount of air blowing over the cooling coil, the temperature of the air coming off the coil can be controlled to suit the outside-air condition and the condition desired in the space being cooled. The cooling coil serves as the dehumidifier for the summer cycle. As warm, humid air comes in contact with the cold surface of the coil, moisture condenses out of the air and drips off the coil to a drain below. Air leaving the cooling coil thus contains less moisture than air entering the coil.

- The blower, or fan, is designed to pull the proper amount of air across the coil and force it out through the supply duct to the several registers.

- The filter section filters both recirculated air and outside air, removing dirt, pollen, and other foreign matter.

- The humidifier is a spray type and puts additional moisture (if needed) in the supply air stream during the winter heating cycle. Its operation is controlled by humidistat in the conditioned space. (Warning: not to place humidistat in the return air duct to mitigate sensor faults due to accumulation of lints and dirt.)

- The air handling unit, insulated on all surfaces, which contains the heating and cooling coils, the blower, and the filters. The outside air duct and the return air duct feed into a mixing chamber behind the blower and filter.

- The outside air intake brings in fresh outside air to meet local code requirements, usually 7.5 L/s per person (refer to AS1668.2) in the conditioned space.

- The return air duct brings air from the conditioned space back to the air conditioner for mixing with outside air and reconditioning.

- The thermostat in the conditioned space acts as a master controller for numerous other controls which keep the entire system in automatic operation.

- Fin-tube radiation near floor may be installed for heating.

The system described is typical of thousands of small to medium size commercial, year round air conditioning installations across the world. Instead of hot water heat, many such systems would circulate warm air directly from the heat exchanger in a gas fired or from an electric heat pump. Some might prefer to use “packaged” air conditioners (in the space) or rooftop units (for a one-story building). The refrigerating unit may also be either an air-cooled or water-cooled chiller. Collectively they are know as direct expansion (DX) systems.